When it comes to construction, manufacturing, and various industries, zinc bar plays a vital role in enhancing durability and corrosion resistance. Whether you're a professional in the field or simply curious about this material, understanding its properties and applications can provide valuable insights. In this article, we will delve into the world of zinc bars, exploring their uses, benefits, and much more.

Zinc bars have been utilized for centuries due to their exceptional characteristics. They are not only durable but also offer cost-effective solutions for numerous industries. Their versatility and ability to withstand harsh conditions make them an ideal choice for a wide range of applications.

Throughout this article, we will cover everything you need to know about zinc bars, from their composition and manufacturing processes to their environmental impact. By the end, you'll have a comprehensive understanding of why zinc bars are essential in modern industries. Let's dive in!

Read also:Michael Pitt The Enigmatic Actor Redefining Hollywoods Landscape

Table of Contents

- What is Zinc Bar?

- Composition and Types of Zinc Bars

- Manufacturing Process of Zinc Bars

- Applications of Zinc Bars

- Benefits of Zinc Bars

- Environmental Impact of Zinc Bars

- Cost Analysis of Zinc Bars

- Common Uses of Zinc Bars in Industries

- Maintenance Tips for Zinc Bars

- Future Prospects of Zinc Bars

What is Zinc Bar?

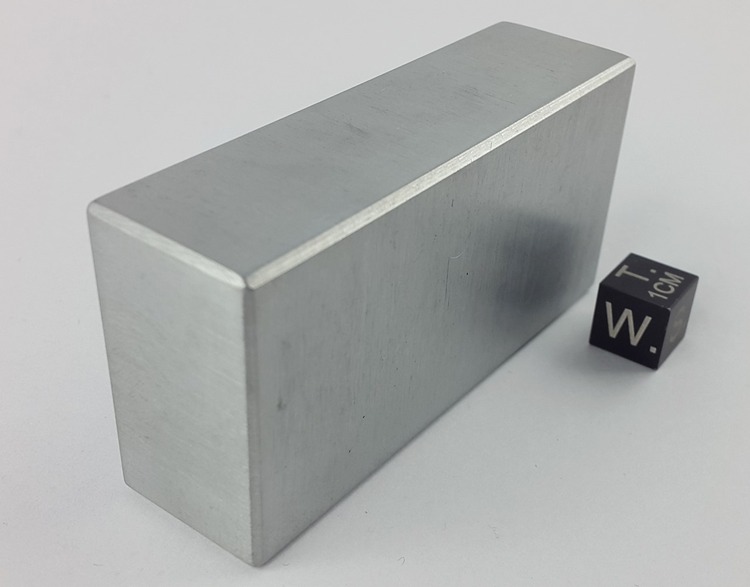

A zinc bar refers to a solid piece of zinc metal, typically shaped into a bar or rod form. Zinc is a bluish-white metal that is highly valued for its corrosion-resistant properties. It is widely used in industries such as construction, automotive, and electronics due to its durability and versatility.

Zinc bars are primarily composed of zinc, but they may also contain small amounts of other metals to enhance specific properties. The purity level of the zinc bar can vary depending on its intended application. High-purity zinc bars are often used in specialized applications where corrosion resistance is critical.

Key Characteristics:

- Corrosion resistance

- High melting point

- Good electrical conductivity

- Thermal stability

Composition and Types of Zinc Bars

High-Purity Zinc Bars

High-purity zinc bars contain over 99.99% zinc and are used in applications requiring minimal impurities. These bars are often employed in chemical and pharmaceutical industries where purity is paramount.

Alloyed Zinc Bars

Alloyed zinc bars are made by combining zinc with other metals such as aluminum, copper, or magnesium. These alloys enhance specific properties, such as strength, ductility, or resistance to wear and tear. Alloyed zinc bars are commonly used in manufacturing and construction industries.

Manufacturing Process of Zinc Bars

The production of zinc bars involves several steps, starting from the extraction of zinc ore to the final shaping of the bars. The process includes:

Read also:Filip Geljo The Rising Star In Contemporary Music

- Mining and Extraction: Zinc ore is mined and processed to extract pure zinc.

- Smelting: The extracted zinc is heated to remove impurities and achieve the desired purity level.

- Casting: Molten zinc is poured into molds to form bars or rods.

- Finishing: The bars are cooled, inspected, and finished to meet industry standards.

This meticulous process ensures that the final product meets the required specifications for various applications.

Applications of Zinc Bars

Zinc bars find applications in a wide range of industries due to their unique properties. Some common applications include:

- Galvanization: Coating steel and iron with zinc to prevent rust and corrosion.

- Battery Production: Zinc is used as an electrode material in batteries due to its electrochemical properties.

- Alloys: Zinc is combined with other metals to create alloys used in die-casting and other manufacturing processes.

- Chemical Industry: Zinc bars serve as raw materials for producing zinc compounds used in fertilizers, pigments, and more.

These applications highlight the versatility and importance of zinc bars in modern industries.

Benefits of Zinc Bars

There are numerous benefits associated with using zinc bars. Some of the key advantages include:

- Corrosion Resistance: Zinc forms a protective layer that prevents rust and corrosion.

- Cost-Effective: Zinc bars offer a cost-effective solution for various industrial applications.

- Environmental Benefits: Zinc is recyclable and has a lower environmental impact compared to other metals.

- Strength and Durability: Zinc bars are strong and durable, making them ideal for long-term use.

These benefits make zinc bars a preferred choice for many industries.

Environmental Impact of Zinc Bars

Zinc is considered an environmentally friendly material due to its recyclability and low carbon footprint. The production of zinc bars involves fewer emissions compared to other metals like steel or aluminum. Additionally, zinc can be recycled multiple times without losing its properties, reducing the need for raw material extraction.

However, it is essential to manage zinc waste responsibly to prevent environmental contamination. Proper disposal and recycling practices can further minimize the ecological impact of zinc bars.

Cost Analysis of Zinc Bars

The cost of zinc bars varies depending on factors such as purity, size, and market conditions. High-purity zinc bars tend to be more expensive due to their specialized applications. On the other hand, alloyed zinc bars may offer a more cost-effective solution for general industrial use.

According to recent market reports, the global demand for zinc bars is expected to increase, driven by growth in construction and manufacturing sectors. This rising demand may influence pricing trends in the coming years.

Common Uses of Zinc Bars in Industries

Construction Industry

In the construction industry, zinc bars are widely used for galvanizing steel structures to enhance their longevity. They are also employed in roofing materials and architectural components due to their aesthetic appeal and durability.

Automotive Industry

The automotive sector utilizes zinc bars for manufacturing corrosion-resistant parts and components. Zinc coatings on car bodies and parts help protect them from rust and environmental damage.

Electronics Industry

Zinc bars play a crucial role in the electronics industry, where they are used in battery production and as a material for electrical components.

Maintenance Tips for Zinc Bars

To ensure the longevity and effectiveness of zinc bars, proper maintenance is essential. Here are some tips:

- Regularly inspect zinc-coated surfaces for signs of damage or wear.

- Clean zinc bars using mild soap and water to remove dirt and debris.

- Avoid exposing zinc bars to harsh chemicals or acidic environments.

- Store zinc bars in a dry, well-ventilated area to prevent moisture buildup.

Following these maintenance practices can significantly extend the lifespan of zinc bars.

Future Prospects of Zinc Bars

The future of zinc bars looks promising, with advancements in technology and increasing demand in various industries. Research and development efforts are focused on improving the properties of zinc bars, such as enhancing their strength and corrosion resistance.

Additionally, the growing emphasis on sustainability and environmental responsibility is driving innovation in zinc production processes. These developments are expected to further expand the applications and benefits of zinc bars in the coming years.

Kesimpulan

In conclusion, zinc bars are an essential material in modern industries due to their exceptional properties and versatility. From construction to electronics, their applications are vast and varied. By understanding their composition, manufacturing process, and benefits, we can appreciate the significant role they play in our daily lives.

We encourage you to share your thoughts and experiences with zinc bars in the comments section below. Additionally, feel free to explore other articles on our website for more informative content. Together, let's continue to learn and grow in our knowledge of materials and their applications.

References:

- International Zinc Association

- U.S. Geological Survey

- World Bureau of Metal Statistics